Germany-based shot blasting technologies specialist Rösler Oberflächentechnik was selected from four equipment manufacturers to provide one of the largest foundries in Türkiye with a shot blast machine, expanding the foundry’s engine block de-sanding and cleaning capacity.

Among other products, the Turkish foundry supplies grey and nodular cast iron engine blocks, which are used in commercial vehicles and ships. The raw castings have dimensions of maximum 900 mm by 330 mm by 140 mm and weigh up to 237 kg.

Previously, the client used two spinner hanger blast machines – one for de-sanding and the other for general cleaning. However, a steadily growing production volume resulted in the shot blasting operation increasingly becoming a bottleneck. Owing to this, the company decided to purchase an additional alternative shot blast system.

Rösler’s RMBS 1-6-400-30 shot blast system was chosen owing to the high degree of automation of the work piece handling and the shot blast process. Compared to spinner hanger machines the RMBS system offers significantly shorter cycle times and requires fewer personnel, says Rösler.

Additionally, by replacing the client’s two existing blast machines, the new system helped provide valuable additional manufacturing space.

Tailored System

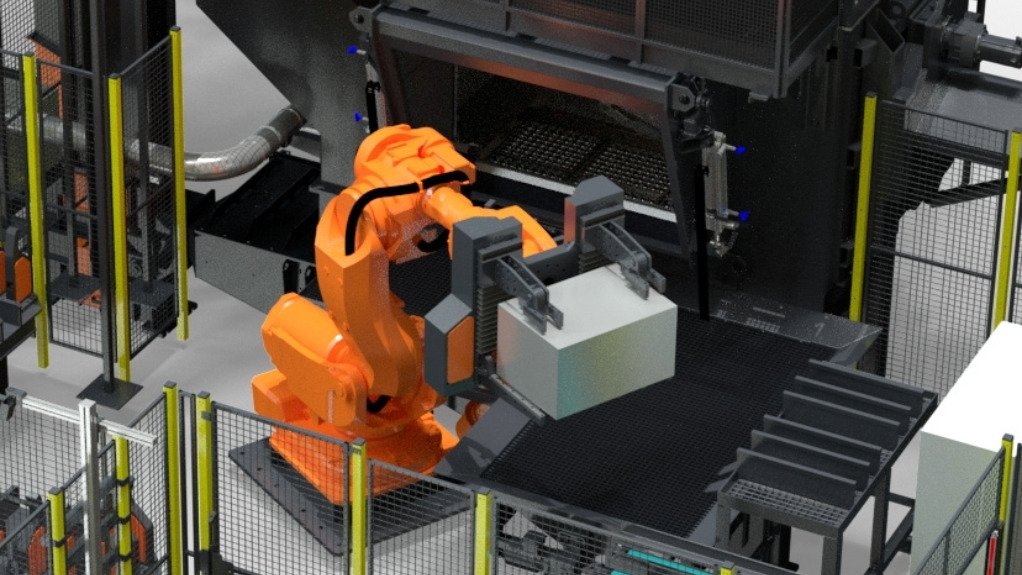

The RMBS 1-6-400-30 blast system can be adapted to the customer requirements and allows for the fully automatic simultaneous blast-cleaning of one large, or several smaller, engine blocks within short cycle times, aided by the machine’s specially engineered gripper-manipulator.

After a robot has precisely positioned an engine block in the blast chamber, the gripper picks up and firmly holds the engine block. Once the blast chamber door has been closed, the blast programme, tailored to specific work pieces, starts. The gripper precisely rotates the work piece through the blast media stream.

To increase the exposure of specific surface areas of the engine block to the blast media, the rotation can be slowed down or interrupted for a pre-defined time. For simultaneous processing of several smaller engine blocks, the engine blocks are mounted to a special work piece fixture. The entire fixture is then picked up by the gripper and rotated through the blast media stream.

Increased Efficiency

With the client’s previous spinner hanger blast solution, the work pieces had to be manually loaded onto a special hanger before they could be blasted, Rösler explains. The new system achieves the required blast results by the targeted movement of the engine blocks through the blast stream.

“The resulting cycle time savings are such that the de-sanding and surface cleaning operation can now be combined into one single process,” says Rösler.

This results in a significant increase in the overall shot blasting capacity, whereby the two spinner hanger blast machines used in the past are no longer required.

Further, the risk of certain work piece areas being shielded from the blast stream by other work pieces has been eliminated.

Minimised Maintenance Costs

Rösler explains that the desired shot blast results are quickly achieved by the six blast turbines, type Gamma 400G-8 HD, each with an installed drive power of 30 kW. These turbines, specially developed for shot blasting in foundries, are equipped with eight throwing blades in the typical Y-design, compared with the standard Gamma turbines with six blades, the company says.

Another significant feature of the HD turbine version is that its housing is lined with “extremely wear-resistant tool steel”. Through this design the throwing blades achieve an up to three times longer uptime than their standard equivalent.

This minimises maintenance work, ensuring significantly higher productivity and cost-efficiency. The design generates an up to 20% higher blast intensity while simultaneously having lower energy consumption.

Additionally, another feature is that both sides of the throwing blades can be used, resulting in significant cost savings for spare parts. Blade changes are facilitated by a quick-change system that requires no removal of the turbine from its housing.

The blast chamber is also designed for high wear resistance, consisting of sturdy manganese steel and is lined with easily replaceable plates made from wear-resistant steel. Areas directly exposed to the blast stream are lined with special cast wear plates, Rösler concludes. ![]()