Fluid handling technology provider Monitor Pumps & Systems’ pumps are not only suited to water-related applications but also primers and paints specially developed for new vehicles, says GM Wim Verhagen.

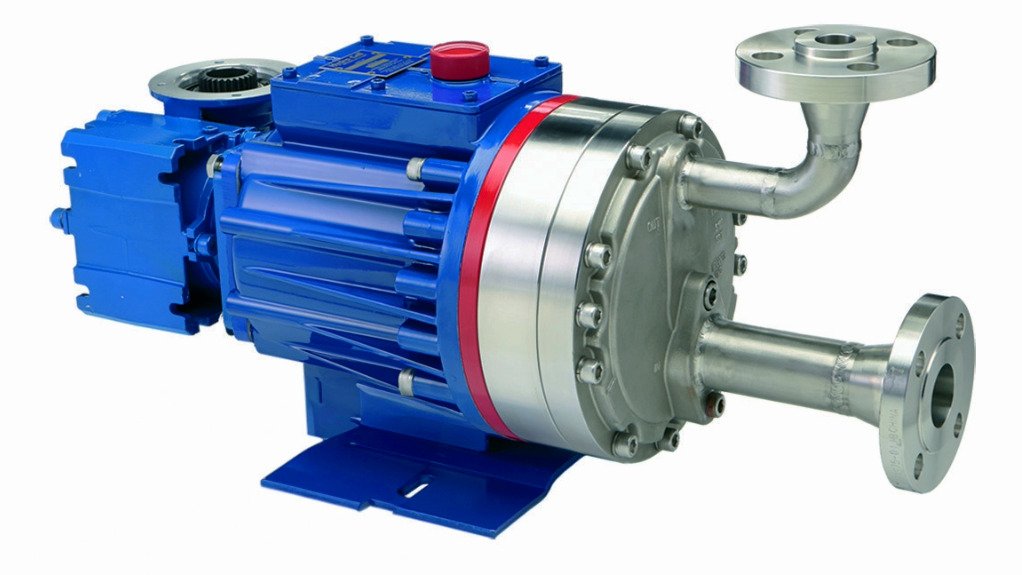

The Wanner Hydra-Cell 600 metering solution pump, which is one of many pumps the company supplies across South Africa, is an effective system that can replace proximate pumping solutions at priming paint refill stations in automotive manufacturing plants.

Verhagen cites the example of a problematic paint priming refill station of a major automaker. The continuously changing dimensions of vehicle bodies caused the air-operated double diaphragm pump to refill inaccurately, leading to out-of-specification frames.

“Switching to a Hydra-Cell P600 metering solutions pump solved the issue,” he says, adding that the pump was integrated with a building management system (BMS), an automation platform and a timer, which, in turn, resulted in accurate refills of paint to within a variance of 380 mℓ for a model.

Consequently, the client saved between R380 000 and R570 000 a month while achieving a full return of investment within the first month.

The Hydra-Cell P600 ensures “consistent, trouble-free operation”, but Verhagen cautions that the sealless design could make it “a bit excessive for low-pressure or simple fuel transfer tasks”.

Where it Matters

The Hydra-Cell P600 pump excels in automotive manufacturing, chemicals processing, mining, oil and gas, and water treatment.

“Its sealless design, precision metering, high-pressure handling and durability make it ideal for abrasive, corrosive and high-viscosity fluids,” he adds.

These features ensure efficiency, reliability and low maintenance in demanding applications.

The pump can easily be integrated into a client’s existing system, owing to its “compact design, precise control and compatibility” with automation platforms and BMSs.

“Monitor Pumps provides expert support, installation guidance and ongoing technical assistance to ensure optimal performance,” Verhagen tells Engineering News.

Further, industries that the company services include those that require coolant delivery, spray systems and testing rigs.

Over the years, Monitor Pumps has successfully introduced Hydra-Cell pumps, including the P600 pump, onto the South African market, where they have gained a “strong reputation” for durability, efficiency and precision.

“Monitor’s expertise in the region, combined with Hydra-Cell’s advanced pump technology, has ensured reliable, strong local support and tailored solutions for South African customers,” concludes Verhagen. ![]()